The Global Tapestry of Commodities Powering Electric Vehicle Batteries

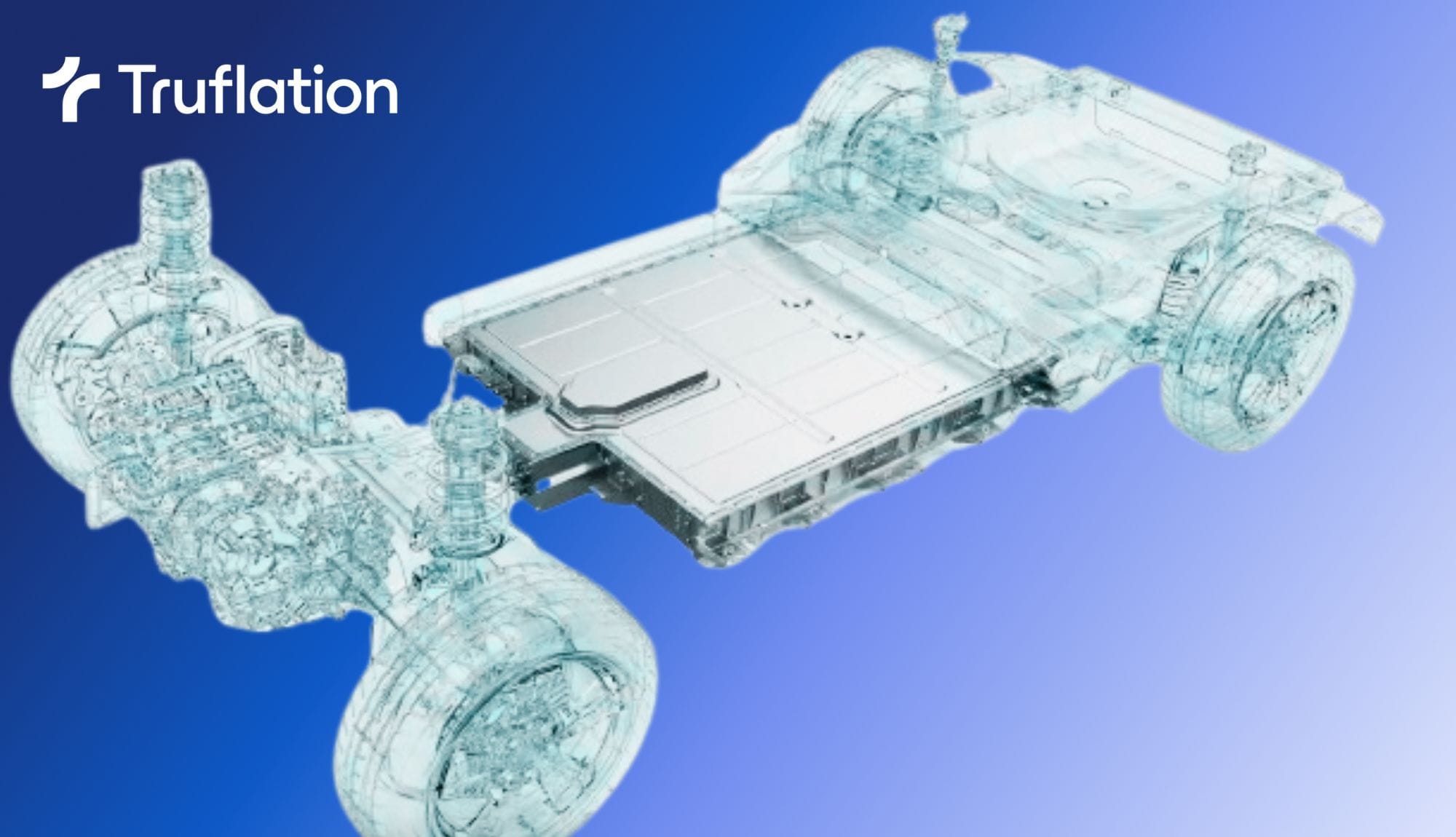

The electric vehicle (EV) revolution hinges on the groundbreaking technology of lithium-ion batteries, propelling the automotive industry into a new era of sustainable transportation. Behind the scenes, an intricate web of commodities forms the backbone of these batteries, with each element playing a pivotal role in their construction and maintenance. From the extraction of lithium in South America to cobalt mining in Africa, the global supply chain for electric vehicle batteries is both complex and interconnected.

Lithium - The Energy Enabler

Lithium, often referred to as the "white gold" of the electric vehicle industry, is a key ingredient in lithium-ion batteries. The majority of the world's lithium reserves are found in the "Lithium Triangle" – a region encompassing parts of Argentina, Bolivia, and Chile. These countries are the epicenter of lithium extraction, utilizing brine evaporation and hard-rock mining methods to extract the precious metal. While Chile leads global lithium production, ethical concerns related to water usage and environmental impact persist, necessitating a balance between resource extraction and sustainability.

READ: Unveiling the Prowess and Investment Potential of Nickel

Cobalt - The Ethical Dilemma

Cobalt, a critical component for stabilizing lithium-ion batteries, has garnered attention for its ethical sourcing challenges. The Democratic Republic of the Congo (DRC) supplies a significant portion of the world's cobalt, but the mining industry in the region has faced allegations of child labor and unsafe working conditions. In response, stakeholders in the electric vehicle supply chain are actively seeking ways to minimize cobalt usage or source it ethically through initiatives like the Responsible Cobalt Initiative, aiming to ensure fair labor practices and environmental responsibility in the mining process.

Nickel - The Range Extender

Nickel is a key player in extending the range and performance of electric vehicle batteries. With the increasing demand for longer-lasting batteries, nickel-rich cathodes are becoming more prevalent in lithium-ion battery chemistries. The majority of the world's nickel production comes from countries like Indonesia, the Philippines, and Russia. The industry is exploring ways to reduce nickel usage or transition to more sustainable extraction methods, given the environmental impact associated with traditional mining practices.

Explore The Truflation Indexes & Data Feeds

Graphite - The Conductive Element

Graphite serves as the anode material in lithium-ion batteries, facilitating the flow of electrons during energy storage and release. The majority of the world's natural graphite is sourced from China, with other notable producers including Brazil and India. The mining and processing of graphite, while less environmentally intensive than some other battery materials, still pose challenges related to water consumption and chemical usage. Efforts to improve mining practices and invest in sustainable technologies are underway to mitigate these concerns.

Manganese - The Stability Factor

Manganese is an essential component in the cathodes of lithium-ion batteries, contributing to their stability and performance. The primary sources of manganese are South Africa, Australia, and China. Sustainable mining practices and recycling initiatives are gaining traction to address environmental concerns associated with manganese extraction.

Aluminum - The Structural Support

Aluminum plays a crucial role in the construction of battery enclosures and structural components, providing strength and durability while minimizing the overall weight of electric vehicles. The world's largest aluminum producers include China, Russia, and Canada. Recycling initiatives and advancements in sustainable aluminum production are vital to reducing the environmental impact of this essential material.

The global supply chain for electric vehicle batteries weaves through continents, linking resource-rich regions with the burgeoning demand for sustainable transportation. As the electric vehicle market continues to grow, the industry faces the dual challenge of meeting the demand for essential commodities while addressing ethical, social, and environmental concerns associated with their extraction. The pursuit of responsible sourcing, recycling initiatives, and sustainable technologies will be crucial in ensuring that the electric vehicle revolution remains a beacon of progress for a cleaner and greener future.

Want to be part of the data revolution? Join our Telegram to always be in the loop!